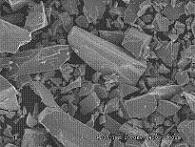

Titanium Carbide Powder

We produce and stock customizable titanium carbide (TiC) powders providing extreme hardness, low coefficient of friction, high wear resistance, and thermal shock resistance.

Chemical Formula

TiC

Synonyms

Titanium carbide, titanium monocarbide, monotitanium monocarbide

Applications

- Wear surface (wear resistant) parts and coatings. Parts and coatings that undergo fretting, abrasion, cavitation, and particle erosion such as cutting tools, nozzles, and bearings.

- Additives. Our titanium carbide powder is added to plastic and rubber parts to reduce wear and as an alternate to metal parts.

Fabrication Methods

- Thermal Spray Process. Titanium carbide powders can be blended with other materials (e.g. Ni) and be thermal sprayed to form hardface coatings on surfaces requiring increased wear resistance.

- Powder Metallurgical (P/M). Titanium carbide powders are pressed into parts through hot or cold pressing and sintering. Some parts include cutting tool tips, dies, and wear parts.

Properties

- Hardness: Knoop - 2470 / Mohs - +9

- Melting Point: 5680°F / 3160°C

- Boiling Point: 8710°F / 4820°C

- Molar mass: 59.89 g/mol

- Density (gm/cc): 4.9-5.2

- Young's Modulus: 439.4 GPa

- Poisson's Ratio: 0.187-0.189

- Linear Thermal Expansion: .02% @ 600°F and 0.8% @ 2000°F

- Appearance: gray powder